Download Brochure

Request A Quote

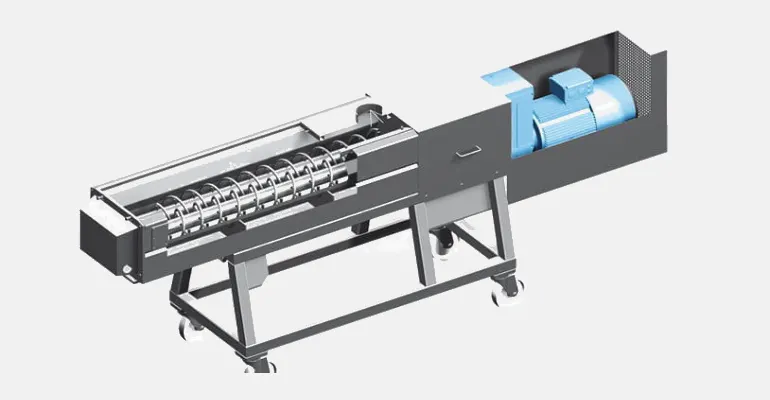

Screw Mixer

A screw mixer, particularly the vertical cone screw mixer (often known as a Nauta mixer), operates

on a highly unique principle to achieve gentle and thorough blending of powders, granules, pastes,

and fragile materials. The mixer consists of a conical vessel with a vertical, rotating screw agitator

that is suspended from a cantilevered arm at the top. This design allows the screw to be fully

supported from above, eliminating the need for a bottom bearing which is a common point of

contamination or product stagnation in other designs.

The mixing action is a combination of two distinct, slow movements: rotation and revolution.

First, the screw rotates on its own axis, which continuously lifts the material from the bottom of the

cone to the surface along its flight. This axial movement is the primary mechanism for convective

mixing. Second, the entire screw assembly revolves around the central axis of the conical vessel,

with the top of the screw following the inner wall of the cone. This revolution ensures that the

screw sweeps a wide area, progressively introducing fresh material to the central lifting action.

The combined effect of the screw’s rotation and revolution creates a three-dimensional, circulating

flow pattern within the conical vessel. As the screw lifts material, it also continuously shears

particles away from the wall. The lifted material then descends by gravity in a mass flow down the

centre of the cone, filling the void left by the upward-moving screw. This constant lifting, horizontal

displacement, and gravity-fed fall ensures that all particles are repeatedly separated, mixed, and

recombined, leading to a high degree of homogeneity.

Features:

Gentle and uniform mixing action

Ideal for fragile & heat-sensitive materials

Vertical cone design ensures full material flow

No bottom bearing reduces contamination risk

Handles powders, granules & pastes

High homogeneity with low power consumption

FAQs

A Screw Mixer is used for gentle and homogeneous mixing of powders, granules, pastes, and fragile materials.

It uses a rotating and revolving vertical screw that lifts material upward while gravity allows it to flow downward.

The cantilevered design eliminates bottom bearings, reducing contamination and product stagnation.

Yes, its low-shear mixing action makes it ideal for fragile and heat-sensitive products.

Pharmaceutical, food, chemical, nutraceutical, and specialty material industries commonly use Screw Mixers.