Download Brochure

Request A Quote

Other Products

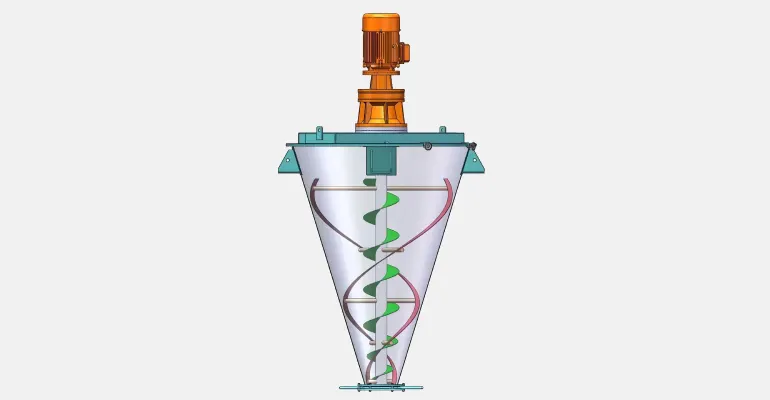

Conical Ribbion Mixer

The Conical Ribbon Mixer, often referred to as a vertical ribbon blender, utilizes a vertical, conicalshaped vessel combined with a specialized ribbon agitator to achieve thorough and gentle blending

of dry powders and granules. Unlike the horizontal U-trough ribbon blender, the conical design

minimizes residual material at the bottom and is supported from the top, eliminating the potential

for a bottom bearing to cause contamination or create a dead spot. This configuration is particularly

valued in industries where hygiene and complete product discharge are critical, such as

pharmaceuticals and food processing.

The central mechanism of the conical ribbon mixer is its double-helix ribbon agitator, which is

mounted on a central vertical shaft. This agitator consists of two ribbons: an outer helix and an inner

helix. The outer ribbon is pitched to lift the material upwards along the inner wall of the conical

vessel, moving it from the narrow bottom toward the wider top section. Simultaneously, the inner

ribbon is pitched in the reverse direction, pushing material downward toward the discharge valve.

This counter-current action creates a balanced, intensive, and gentle mixing environment.

The working principle generates a constant, three-dimensional flow of material. The upward

movement from the outer ribbon and the downward flow from the inner ribbon ensure that particles

are continuously cycled, eliminating static zones and promoting rapid dispersion. As the material

reaches the top of the cone, it naturally cascades downward by gravity, flowing back into the path of

the agitator to be re-circulated. This large-scale convective movement, combined with the mild

shear forces generated by the ribbons, rapidly breaks up soft agglomerates and ensures a high

degree of homogeneity.

Features:

Uniform and gentle mixing performance

Vertical conical design ensures complete discharge

Double-helix ribbon for efficient blending

No bottom bearing reduces contamination risk

Ideal for powders and granules

Eliminates dead zones with 3D material flow

FAQs

It is used for homogeneous mixing of dry powders and granules in pharmaceutical, food, and chemical industries.

Inner and outer ribbons move material upward and downward simultaneously, creating continuous counter-current mixing.

The conical shape ensures full material flow, minimal residue, and complete discharge.

Yes, the top-supported design without a bottom bearing minimizes contamination and improves cleanliness.

It is suitable for free-flowing powders, granules, and mildly cohesive materials.